Leave Your Message

In today's fast-paced industrial environment, maintaining a clean and organized warehouse is crucial for operational efficiency and worker safety. One effective solution for achieving this is the use of a Warehouse Vacuum Sweeper. Unlike traditional cleaning methods, these specialized machines are designed to handle large debris and fine dust, ensuring that your workspace remains clean and free of hazards. However, with various options available in the market, choosing the best Warehouse Vacuum Sweeper that meets your specific business needs can be a daunting task.

When selecting a Warehouse Vacuum Sweeper, it is vital to consider factors such as the size of the area to be cleaned, the types of materials commonly found in your warehouse, and the level of daily usage. Additionally, understanding the features that enhance performance, such as filtration systems and maneuverability, can significantly impact your cleaning operations. This guide will provide insights into the essential considerations and best practices for selecting the right Warehouse Vacuum Sweeper, ensuring that your investment leads to a cleaner, safer, and more productive work environment.

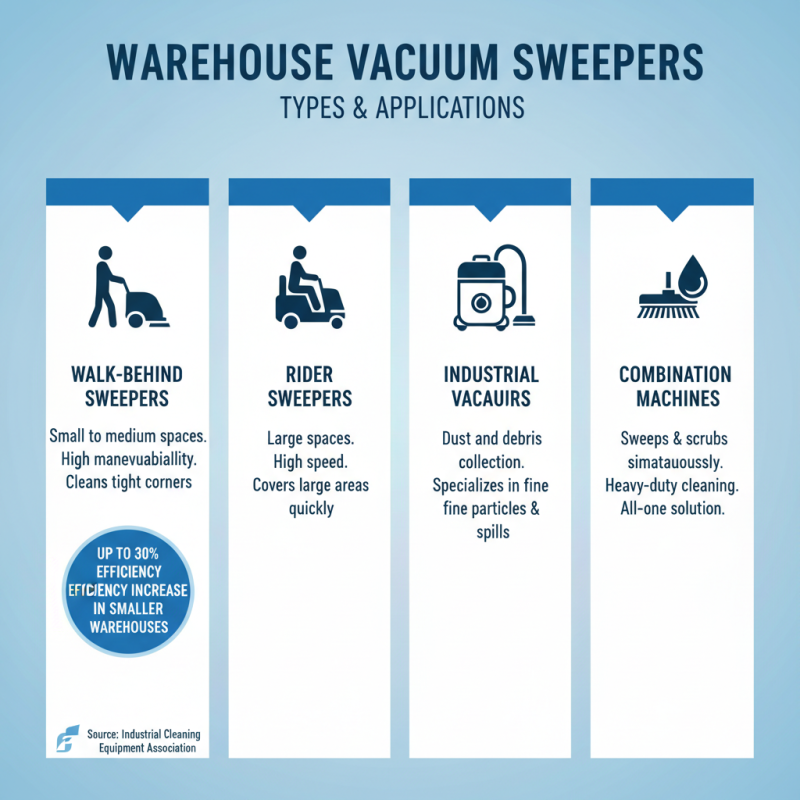

When selecting a warehouse vacuum sweeper, it’s essential to understand the different types available in the market to meet specific operational needs. Warehouse vacuum sweepers generally fall into four main categories: walk-behind sweepers, rider sweepers, industrial vacuum cleaners, and combination machines. Walk-behind models are suitable for smaller spaces and provide excellent maneuverability, allowing operators to clean tight corners effectively. According to the Industrial Cleaning Equipment Association, utilization of walk-behind sweepers can increase efficiency in smaller warehouses by up to 30%, significantly enhancing productivity without requiring significant floor space.

Rider sweepers, on the other hand, are designed for larger areas, offering higher capacities and reduced labor times. Reports from the International Facility Management Association highlight that rider sweepers can cover up to 60,000 square feet per hour, making them ideal for expansive warehouse environments. Industrial vacuum cleaners complement these sweepers by providing the ability to handle fine dust and heavy debris, ensuring compliance with health and safety regulations. Combination machines, which integrate sweeping and vacuuming functionalities, represent an emerging trend, promising versatility and enhanced cleaning efficiency. By carefully considering these categories and their applications, businesses can choose a vacuum sweeper that aligns perfectly with their operational requirements, ensuring a cleaner and safer work environment.

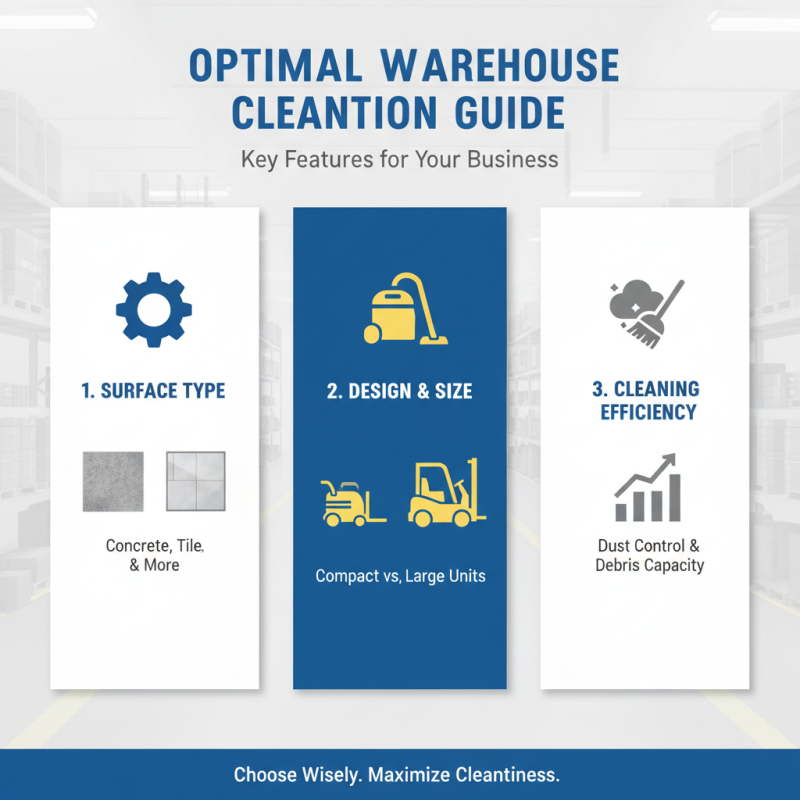

When selecting the best warehouse vacuum sweeper for your business, it's crucial to evaluate several key features to ensure it meets your operational needs. One of the primary aspects to consider is the type of surface it will be used on. Different models are designed for various flooring materials, such as concrete or tile, which can affect the sweeper's efficiency and the quality of the cleaning. Additionally, consider the design of the vacuum sweeper; compact models might be necessary for tight spaces, while larger units can cover vast areas more quickly.

Another essential feature is the vacuum's filtration system. A high-quality filtration system is vital for maintaining air quality, especially in environments where dust and allergens can pose health risks to employees. Look for vacuums equipped with HEPA filters, as they effectively capture small particles and contribute to a healthier workspace. Moreover, assess the capacity of the vacuum’s collection tank, as a larger tank can minimize downtime for emptying and maximize productivity during cleaning operations. By focusing on these features, you can select a warehouse vacuum sweeper that aligns with your specific business requirements.

When analyzing the cost-effectiveness of warehouse vacuum sweepers for businesses, it is essential to consider both initial investment and long-term savings. According to a report by Research and Markets, the global warehouse equipment market is projected to reach $40 billion by 2026, underscoring the increasing importance of efficient cleaning technologies in warehouse operations. A well-chosen vacuum sweeper can significantly reduce labor costs by minimizing the time needed for floor maintenance. On average, businesses that implement automatic or semi-automatic sweepers report up to a 30% reduction in cleaning time, allowing employees to focus on more value-added tasks.

Moreover, the sustainability aspect cannot be overlooked. A study published by the International Journal of Production Research indicates that effective cleaning not only improves workplace safety but also enhances overall productivity by up to 15%. This productivity spike often compensates for the initial costs of acquiring a warehouse vacuum sweeper. Additionally, utilizing sweepers that operate on low energy can lead to dramatic savings in utility costs, contributing to better overall financial health for the business. By carefully evaluating the features and operational efficiencies of different models, companies can ensure that their investment in vacuum sweepers yields maximum returns.

When choosing a warehouse vacuum sweeper, one crucial factor to consider is the maintenance requirements associated with each model. Different sweepers come with varying levels of complexity in their design, which directly affects the frequency and type of maintenance needed. For instance, some models may have advanced filtration systems that require regular cleaning and replacement, while others might utilize simpler HEPA filters that demand less frequent upkeep. Understanding these requirements can save businesses both time and money in the long run.

In addition to filter maintenance, the overall durability and robustness of the vacuum sweeper play a significant role in determining its upkeep needs. Models designed for heavy-duty use are often built with more durable components that withstand wear and tear better than lightweight options. However, they may still require routine inspections and part replacements to ensure optimal performance. Businesses should also consider the availability of service and parts from suppliers, as easy access to support can greatly enhance the effectiveness and lifespan of the equipment. By thoroughly assessing these maintenance aspects, companies can select a vacuum sweeper that balances performance with manageable upkeep, ultimately fostering a more efficient warehouse environment.

This chart illustrates the average annual maintenance hours required for various types of warehouse vacuum sweepers, helping businesses choose the right equipment based on their maintenance capabilities.

When selecting a warehouse vacuum sweeper, it is crucial to consider the specific standards and regulations that apply to your industry. Various sectors may have distinct cleaning requirements that adhere to health, safety, and environmental guidelines. For instance, the Occupational Safety and Health Administration (OSHA) provides regulations that mandate the maintenance of a clean and safe workplace to prevent accidents and ensure worker safety. A report from the National Institute for Occupational Safety and Health (NIOSH) estimates that poorly maintained environments can lead to injuries costing businesses over $1 billion annually.

In addition, industries such as food and pharmaceuticals have stringent cleanliness standards governed by the Food and Drug Administration (FDA) and the Environmental Protection Agency (EPA). These regulations require the use of equipment that minimizes contamination risks and complies with environmental safety standards. A 2022 study by the Institute of Supply Chain Management revealed that 67% of warehouses in these sectors reported their cleaning protocols directly influence product safety and compliance ratings. Thus, when choosing a warehouse vacuum sweeper, ensure it meets the necessary industry certifications and alignment with these regulatory obligations to safeguard both your operations and overall sustainability.

| Feature | Description | Industry-Specific Standards |

|---|---|---|

| Suction Power | The ability of the vacuum to effectively pick up debris and dust. | Must meet OSHA standards for workplace safety and dust control. |

| Tank Capacity | The volume of waste material the vacuum can hold. | Compatibility with specific industries like food processing or pharmaceuticals. |

| Mobility | Ease of movement around the warehouse. | Compliance with industry ergonomics and safety regulations. |

| Filter Type | The type of filtration system the vacuum uses to capture dust. | Must conform to HEPA filtration standards in sensitive environments. |

| Noise Level | The sound produced during operation. | Requirements for noise control in workplace settings. |

| Durability | Resistance to wear and tear during extensive use. | Industry-grade standards for long-term equipment usage. |